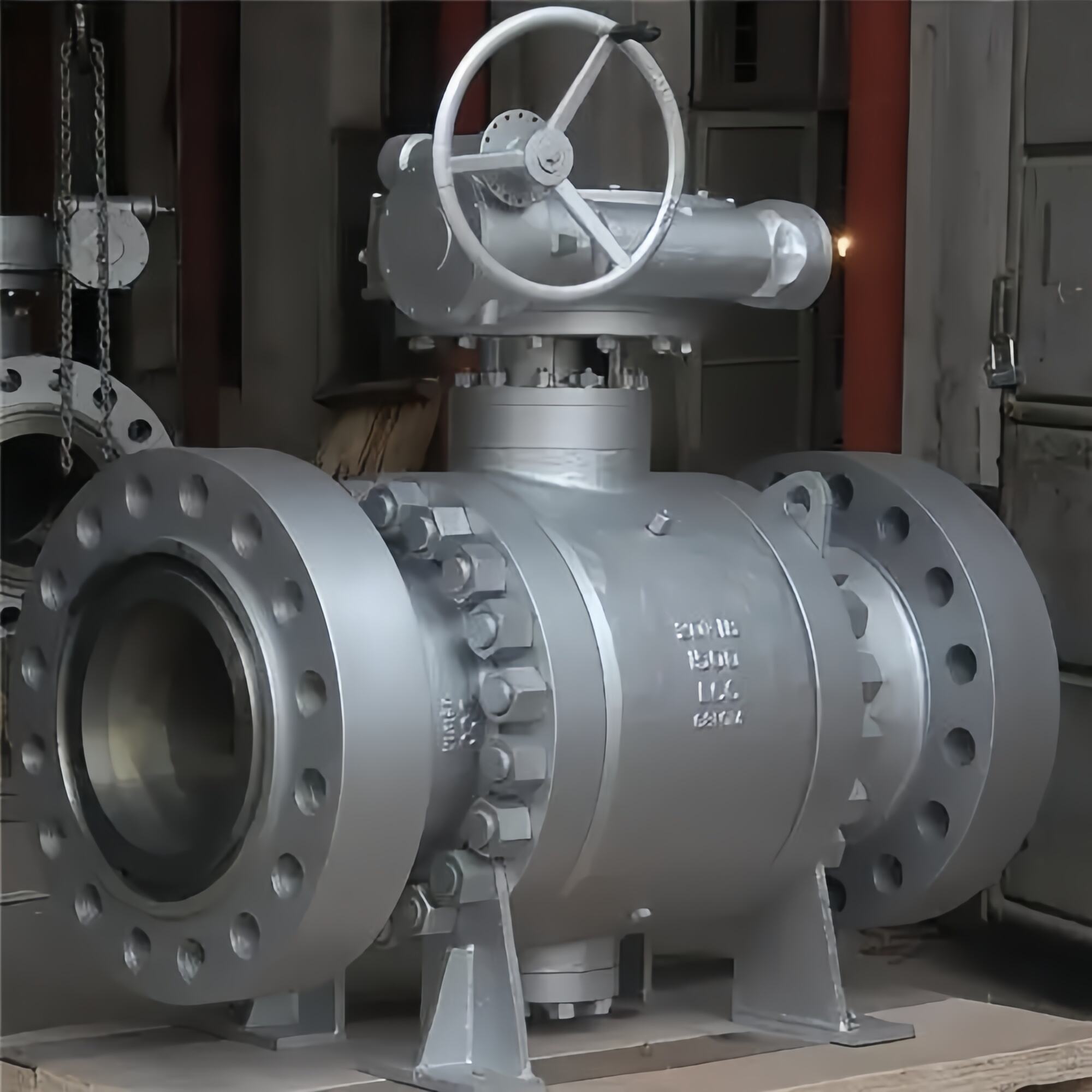

The valve seat of ANSI flange turbine ball valve adopts a double-lip sealing structure design to enhance sealing performance and reduce operating torque. A variety of valve seat materials, suitable for a wide range of applications. Explosion-proof structural design of the valve stem: The valve stem is bottom-mounted to prevent it from flying out under pressure. At the same time, it is guided by PTFE material to reduce valve stem friction and operating torque. Fireproof and anti-static structural design; at the same time, specific structural forms can be designed according to customer requirements or working conditions. The high platform structure can directly install the drive device.

ANSI Flange Turbine Ball Valve

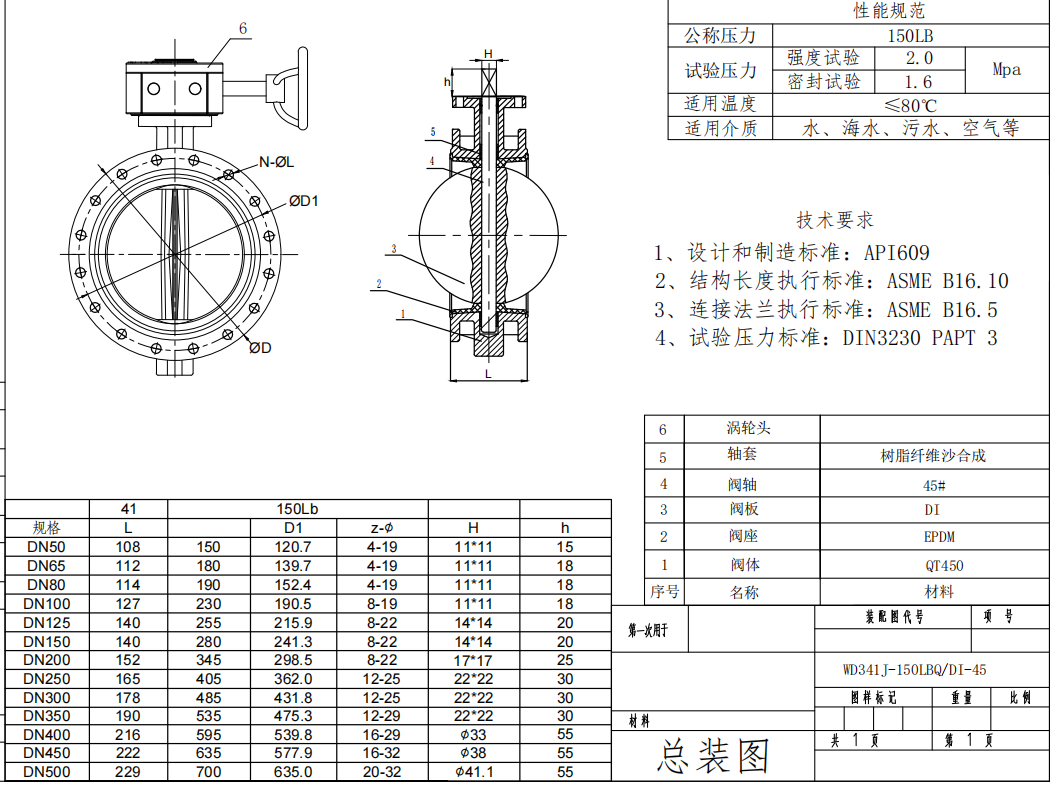

- Nominal pressure: 150LB

- Strength test: 3.0Mpa

- Sealing test: 2.2Mpa

- Air seal test: 0.6Mpa

- Valve body material: WCB(C), CF8(P), CF3(PL),

- CF8M(R), CF3M(RL)

- Applicable media: water, steam, oil, nitric acid, acetic acid

- Applicable temperature: -29℃~150℃

FACTORY STRENGTH

×

×